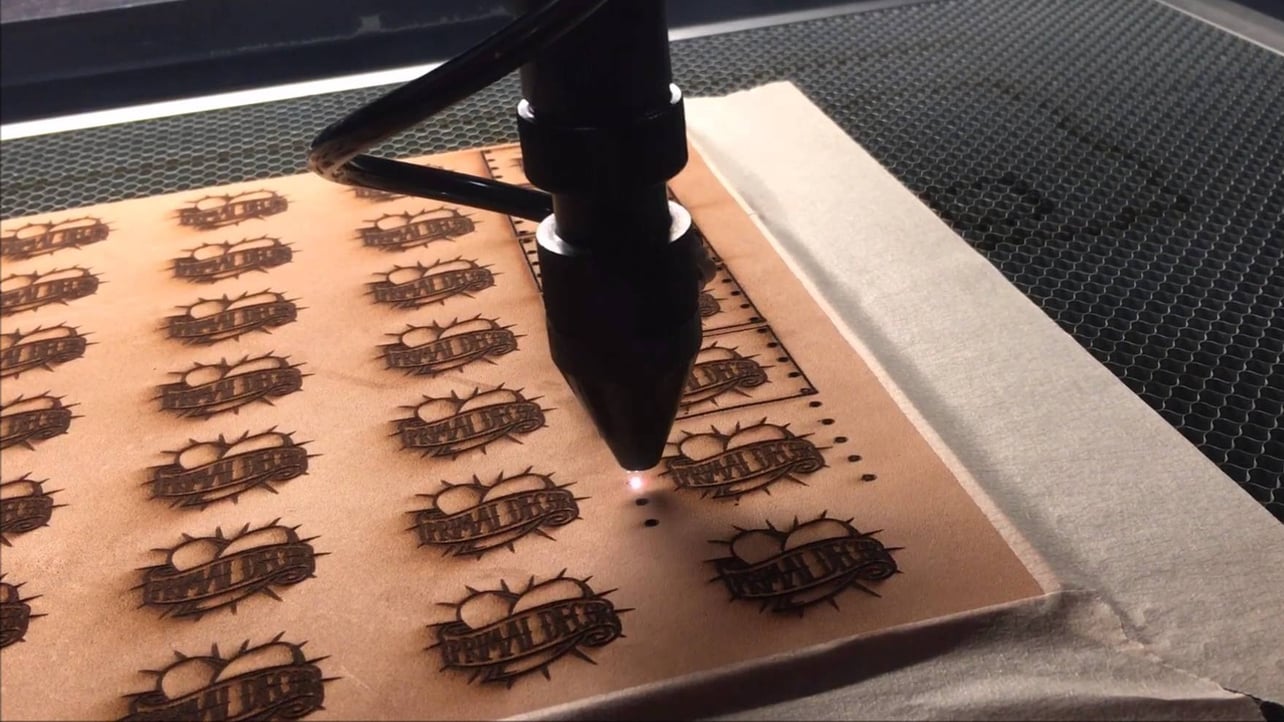

Used in various industrial applications this process can create permanent marks laser marking remove contaminants and coatings from surfaces laser cleaning modify a part s roughness laser texturing cut through a surface laser cutting and much more.

Laser etching painted surfaces.

The surface paint layer evaporates revealing the material beneath.

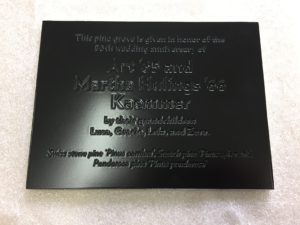

This method provides excellent laser engraving results.

Laser ablation occurs when a laser beam removes material from a localized area.

Each one of our laser marking machines has the ability to mark a variety of surfaces and substrates including painted materials.

One of the most important aspects of a tykma electrox laser marking system is its versatility.

We can handle flat or contoured surfaces within a 250mm marking field and a wide variety of substrates.

Information is applied on various painted surfaces by laser beam.

Laser marking on the other hand is a broader category of methods to leave marks on an object which also includes color change due to chemical molecular alteration charring foaming melting ablation and more the technique does not involve the use of inks nor does it involve tool bits which contact the engraving.

Laser engraving is the practice of using lasers to engrave an object.

The fractured glass surface will produce a frosted appearance but can be rough and chipped depending on the type of glass that is being engraved.

Equipment emerald can provide highly decorated back lit or surface decorated paint and laser etched components.