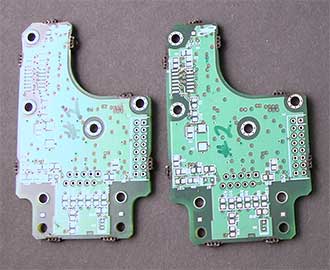

I am going to walk you through the process of prototyping a printed circuit board using a laser cutter and supplies from your local radioshack and hardware store.

Laser cutting fiberglass pcb.

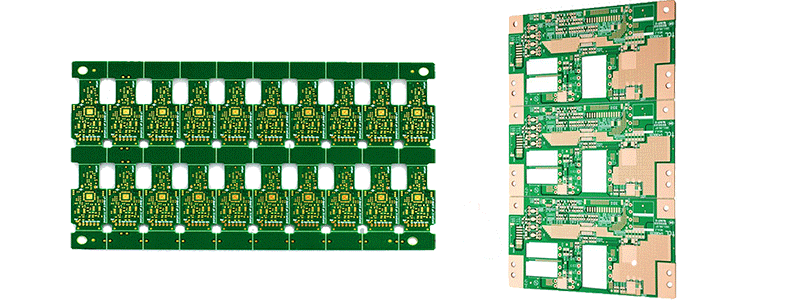

1 coat pcb stock with spray paint 2 laser cut a spring form alignment jig 3 optimize your board layout for fabrication 4 generate vector art for the cutter 5 etch away black spray paint with the laser on both sides 6 chemically etch away exposed copper 7 laser cut through holes in the exposed board 8 tricks and.

Back to tutorial index.

Custom pcb prototyping using a laser cutter.

Especially the contactless processing through the laser beam and the therewith related non deforming laser cutting as well as the high precision are crucial arguments for the application of laser technology in textile processing.

60 watt co 2 laser 30 watt fiber laser.

Large format laser systems are optimally suitable for the cutting of textiles made of fiberglass.

Laser cutting a pcb with a co 2 fiber trotec laser cutter introduction.

Laser etching pcb s was also of interest to me as i was hoping to get rid of the messy fecl3 etching but cutting that copper would require quite a bit more power i understand.

This is a process i have perfected after several prototypes i created as part of my t.